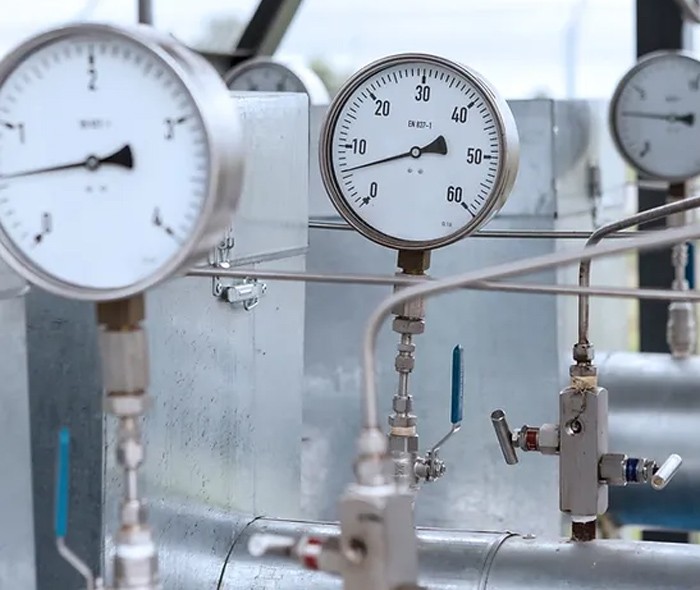

Compressed Dry Air (CDA)

Compressed Dry Air (CDA) is the very critical utility used in semiconductor manufacturing. 365 Days up time is virtual.

Huge highly powered consumption systems in the semiconductor operation.

Overall Efficiency of the CDA Systems can be achieved by Compressor Efficiency, Cooling water flow balancing, Room Air Temperature Control, Air Dryer Efficiency, VSD –IE4 Motors ,Used Cooling Tower Water for Air Compressor and Air Dryer Cooling, incorporate After Cooler in the Design c/w cooling with Chilled water systems, Leak free installation, Low pressure loss distribution Systems and Low CDA Supply Pressure.

Our Solution

Provide Engineering Solutions for Greener Compressed Dry Air Systems – Energy Efficient and CO2 Deductions.

Provide Engineering solutions that will meet NEA Energy Efficiency requirements, 365days operation , and continuous monitoring at Facility SCADA.

Design the CDA Plant consists of Air Compressors, Air Dryers ,Filters and Distribution Pipe Line, Electrical Systems for Air Compressor, Cooling water systems, HVAC for Air Compressor , Instrumentation & Controls, FMCS monitoring.

Design review with End user at 30%,60% and 90%.

Provide Detailed Design (Technical Specification, Air Compressor ,Air Dryer Specification, Pressure Loss Calculations, Schematic Layout, Distribution Layout)e, Tender Package including BOQ.

Market Sourcing , Tender Review and Appoint Contractor.

Issue For Construction (IFC) Drawings.

Construction Management to make sure installation in line with Design Intend, Manage the Various order and complete the Installation ON TIME.